In conjunction with UMB Bank, the MCRR embarks on a new fund-raising scheme.

Check here for details.

Thursday, November 27, 2008

Boiler Washing! (2008 Edition)

Every fall after the various operating events, the volunteers of the MCRR clean the engines and quite literally, wash the boilers.

The following pictures and text describe the washing of the Henschel (16) and Baldwin Mogul (6) which took place on 1 November 2008, the day following the last Ghost Train.

Who would expect a November day to be warm enough to be comfortable without a jacket? A beautiful sunny sky and temperatures in the high 50Fs allowed the staff to deal with two engines in one day. The Shay (9) was not attempted today since it will be in service for North Pole Express . The Shay's washing usually is problematic due to it being mid December!

Volunteer Bill showing what happens after the smoke box of the 16 is cleaned. Several inches of soot accumulated. Since the 16 is coal burning, the soot isn't oily, just dry, black, fine powder.

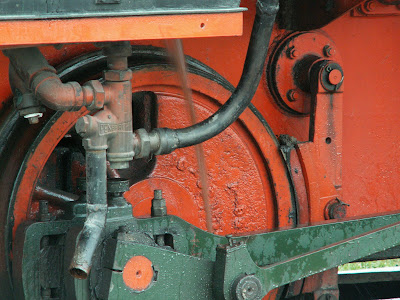

"Shop Supervisor" Mike E. is checking the action of the train brake in the 16.

One of the volunteers is seen crawling under the 6's cab behind the read drivers to get himself ready for the high pressure hose. The high pressure hose is fitted with various nozzles which allows the operator to get a stream of water into all the places inside the boiler.

Not shown is the staff's effort to remove all the boiler plugs. Depending on the use of leak-stop compounds, the plug removal usually takes about 2 hours per engine. (Last year, the smoke box boiler plug had a leak-stop compound which caused its removal to take several days! Generous use of the torch finally solved the problem. )

Shop water is sucked through the pump attached to the tractor's PTO to give it sufficient pressure for the cleaning.

Jesse V. operates the water flow while Griffin operates the nozzle.

Griffin W. takes a breather from the washing.

Jesse V. smiles for the camera. Notice how he is wearing a tractor tire for protection? Boiler washing is a sloppy job!

A close up of Griffin under the 6 reaching up to the rear firebox boiler plugs.

Dustin B. and Bill discuss the next few tasks for the 16's bath. The smoke box door is open for the removal of soot and eventual pressure washing. The 55g barrel to the engine's left is a special chimney vacuum lent to us by another volunteer, Steve B (not shown).

This shot is from the engine's left side; Griffin has to get close up and personal with the engine to give it a good bath. Notice the water draining from the blow-off port. In this picture, the water is running clean -- a good sign.

Jesse V. watches while Griffin continues to flood the boiler.

Jesse V. is checking the outflow for "chunks." Our aggressive water treatment plan is designed to minimize boiler deterioration. The "jury is out" on its effectiveness until the drain water is analyzed and visual inspections take place.

Dustin B. hooks up the powerful air compressor's hose to the 16's air brake storage tank. This allows the engine's operator to use the brakes as they propel engine back and forth in their attempt to rid the lines, cylinders, and other passageways of residual water.

The boiler is pressurized by the external air compressor. The pressure, although far less than typical operating steam pressure, is enough to make the engine travel to the extent that the hoses allow it to move.

After attaching the hoses to the engine, Dustin checks the air compressor for proper operation.

"Shop Supervisor" Mike E. takes a well deserved rest from the cleaning operation.

Bill and Griffin discuss the next phase of the boiler washing while the PTO operated pump spews water from the auxiliary connection.

Jesse V. is washing the 16's boiler from the fireman's upper access hole.

Another shot of Jesse, this time from the left side of the engine.

Water can be seen dripping from numerous places as the boiler gets the high pressure blast

Griffin W. in a rare shot with his "son" Brian Y. Brian is operating the pump while Jesse is hosing down the boiler.

The ash screens are hosed off with the output of the pressure washer.

Dustin B. uses the tractor powered pump to clean the smoke box and flues of the 16.

Shower time!

Every bit of soot and ash needs to be removed from the smoke box.

After washing the 6's boiler, Griffin operates the pump while Dustin does the dirty details on the 16.

Dustin awaits the water to be turned on.

Water drains from the open boiler plugs on the engine's right side.

The water is running red ( ! ) from rust that has accumulated inside the boiler. The washing continues until it runs clear insuring all damaging material is removed from the boiler.

The rust leaves numerous traces on the track's ballast.

The following pictures and text describe the washing of the Henschel (16) and Baldwin Mogul (6) which took place on 1 November 2008, the day following the last Ghost Train.

Who would expect a November day to be warm enough to be comfortable without a jacket? A beautiful sunny sky and temperatures in the high 50Fs allowed the staff to deal with two engines in one day. The Shay (9) was not attempted today since it will be in service for North Pole Express . The Shay's washing usually is problematic due to it being mid December!

Volunteer Bill showing what happens after the smoke box of the 16 is cleaned. Several inches of soot accumulated. Since the 16 is coal burning, the soot isn't oily, just dry, black, fine powder.

"Shop Supervisor" Mike E. is checking the action of the train brake in the 16.

One of the volunteers is seen crawling under the 6's cab behind the read drivers to get himself ready for the high pressure hose. The high pressure hose is fitted with various nozzles which allows the operator to get a stream of water into all the places inside the boiler.

Not shown is the staff's effort to remove all the boiler plugs. Depending on the use of leak-stop compounds, the plug removal usually takes about 2 hours per engine. (Last year, the smoke box boiler plug had a leak-stop compound which caused its removal to take several days! Generous use of the torch finally solved the problem. )

Shop water is sucked through the pump attached to the tractor's PTO to give it sufficient pressure for the cleaning.

Jesse V. operates the water flow while Griffin operates the nozzle.

Griffin W. takes a breather from the washing.

Jesse V. smiles for the camera. Notice how he is wearing a tractor tire for protection? Boiler washing is a sloppy job!

A close up of Griffin under the 6 reaching up to the rear firebox boiler plugs.

Dustin B. and Bill discuss the next few tasks for the 16's bath. The smoke box door is open for the removal of soot and eventual pressure washing. The 55g barrel to the engine's left is a special chimney vacuum lent to us by another volunteer, Steve B (not shown).

This shot is from the engine's left side; Griffin has to get close up and personal with the engine to give it a good bath. Notice the water draining from the blow-off port. In this picture, the water is running clean -- a good sign.

Jesse V. watches while Griffin continues to flood the boiler.

Jesse V. is checking the outflow for "chunks." Our aggressive water treatment plan is designed to minimize boiler deterioration. The "jury is out" on its effectiveness until the drain water is analyzed and visual inspections take place.

Dustin B. hooks up the powerful air compressor's hose to the 16's air brake storage tank. This allows the engine's operator to use the brakes as they propel engine back and forth in their attempt to rid the lines, cylinders, and other passageways of residual water.

The boiler is pressurized by the external air compressor. The pressure, although far less than typical operating steam pressure, is enough to make the engine travel to the extent that the hoses allow it to move.

After attaching the hoses to the engine, Dustin checks the air compressor for proper operation.

"Shop Supervisor" Mike E. takes a well deserved rest from the cleaning operation.

Bill and Griffin discuss the next phase of the boiler washing while the PTO operated pump spews water from the auxiliary connection.

Jesse V. is washing the 16's boiler from the fireman's upper access hole.

Another shot of Jesse, this time from the left side of the engine.

Water can be seen dripping from numerous places as the boiler gets the high pressure blast

Griffin W. in a rare shot with his "son" Brian Y. Brian is operating the pump while Jesse is hosing down the boiler.

The ash screens are hosed off with the output of the pressure washer.

Dustin B. uses the tractor powered pump to clean the smoke box and flues of the 16.

Shower time!

Every bit of soot and ash needs to be removed from the smoke box.

After washing the 6's boiler, Griffin operates the pump while Dustin does the dirty details on the 16.

Dustin awaits the water to be turned on.

Water drains from the open boiler plugs on the engine's right side.

The water is running red ( ! ) from rust that has accumulated inside the boiler. The washing continues until it runs clear insuring all damaging material is removed from the boiler.

The rust leaves numerous traces on the track's ballast.

-Steam.Airman

MCRR Member Kicks-off the "Number 2 Rebuild" fund

MCRR member John W. made a generous donation to the railroad's Engine 2 rebuilding fund. There are a few pictures of him presenting the check to the MCRR Board of Directors...but I misplaced them!

Check back every so often; once I find them, they will be posted along with some more text about the donation and the rebuilding fund.

Check back every so often; once I find them, they will be posted along with some more text about the donation and the rebuilding fund.

Tuesday, November 4, 2008

The 2008 edition of Midwest Haunted Rails

Ahhhhhhhh...it feels so good when I stop banging my head against the wall.

"Midwest Haunted Rails" (also known as "Ghost Train," "Spook Train," and a few other unmentionables) is over. This blog entry shows some of the highlights and lowlights of the four weekend event.

The event centers around the animated objects in the south station. A few new things come each year and some of the old things may not reappear. A comprehensive website containing many pictures of the south station's objects can be found at w w w . g h o s t t r a i n . o r g.

Saturday, October 11, was the first night of operation. Mid October can have weather ranging from "incredible" to "incredibly bad." With afternoon temperatures of 80F and a clear sky, "incredible" correctly described the weather.

Several shop crew volunteers rearranged cars to make the two Haunted Rail trains. Between the Old Threshers' Reunion and the two special operating events, the trains were a mess. The staff moved one car at a time to its destination train until the job was complete. While this should be a trivial operation, one car was particularly fussy and refused to pass backward through the Museum B switch, derailing in the process. An otherwise uneventful afternoon turned gray but the new MCRR CASE backhoe saved the day.

Two of the three steam locomotives (6 and 9) were fired up and ready on time. The crowds were light but enough were present to operate two trains for most of the evening.

The next weekend, October 17 and 18, tried our patience.

Friday's weather fell into the "incredibly bad" category. It was cool and rainy all day which made doing anything outside uncomfortable. The ground was still saturated from heavy rains a few days earlier. Our experience of a low Friday night turnout proved consistent with years past. Fortunately the hardware worked flawlessly.

Saturday was the opposite of Friday: warm, clear skies, a gentle breeze...and crowds that we've never seen! Anticipating the masses, all three locomotives were fired up. By 6 PM, the 6 was pulling passengers and the 9 was ready to hook up to its train only there was no engineer. The MCRR's Matt C. stepped into the 9's cab and was off to get the cars. After a successful air brake test, the 9 was ready for passengers. The 16's fire was banked in anticipation of it being needed to replace the 6 or the 9.

On 9's initial trip to the north station, everyone in the cab remarked that the engines didn't sound right. Oh well...just our imagination. With a full load of passengers, the 9 was on its way to the south station.

Then it happened: just 250 feet from the north station, the 9 stopped dead in its tracks (or more aptly, in its "track"). There were lots of MCRR crew members all scratching their heads about what happened. During the head scratching, Dustin B. ran across McMillan Park to get the 16 at operating pressure. Griffin W. raced back to get the 14, the diesel switch engine, with the intentions of pulling the 9 and its train to the north station, discharging its passengers and then pulling it to the shop.

The crowds kept building and were wondering what was going on. Hahaha...the shop crew was wondering what was going on! Meanwhile, engineer Eric S. was squeezing performance out of the 6 that no one had ever seen before. Fireman Abe S. had his hands full keeping the steam pressure high enough for the 6 to pull up the hill but not pop-off and keep enough water in the boiler. Later that evening, Abe remarked that he had never been so busy on that or any MCRR locomotive.

While the 6 was performing miracles in Eric skillful hands, the 16 was at pressure and was moved to the cars left behind by the 9. Murphy struck again; the 16's air brakes would not work! The 14 towed the 16 away and then it was hooked to the 9's train. With some jury rigging, electricity for the coachs' lights was secured and the 14 roared into service, operating for the rest of the evening.

A few volunteers in the shop ("Shop Supervisor" Mike E. and Jim B.) examined the 9's steam cylinders and found that the D valve linkage had come loose effectively setting the front cylinder into reverse while the center and rear cylinders were in forward motion. No wonder the 9 stopped so suddenly. By the time this was corrected, the other trains had been parked and the customers had left the park -- and it was midnight. For the next two weeks further investigations uncovered excessive drive train misalignment which only amplified the original D valve problem.

Weekend 3, October 24 and 25, were repeats of the previous weekend: cold and rainy on Friday, warm and clear on Saturday. The 6 and 16 worked as intended while the 9 absorbed hours of labor correcting the drive shaft misalignment. Having the 6 and 16 pleased the crowds (there is something about steam!) and the two engines pleased the crews.

The next few pictures show Jesse V. taking one of the 9's trucks apart to determine why the drive shaft was out of alignment.

The next picture shows Jesse holding a section of a bandsaw blade which was used as a shim by the previous owners of the 9, West Side Lumber. Not only were sections of band saw being used as shims, the adjustments had been welded in place, apparently to keep them from coming loose while in the field.

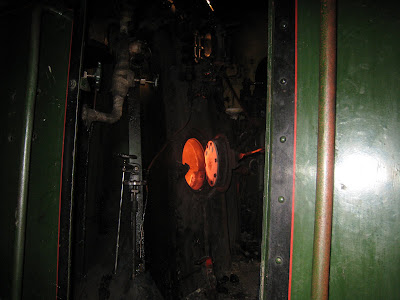

Fireman Dustin B. checks the fire inside the 16's boiler early in the afternoon.

With the 16 at full pressure, it was used to move the 9 back and forth so the staff could visually check the workings of the multiple drive shafts.

As the 16 is doing yard work, the 6 is being brought up to operating pressure.

After dark, the engines take on a different look. Here, the 6 passes the water tower at the north station.

Fireman Dave R getting a few laps of operating time with the 6's boiler in between his long shifts as "spook house" manager.

The 16 pulling into north station.

Fireman Dustin opens the firebox door to feed it some more coal for its trip to the south station. A nice thing about the oil burners (the 6 and the 9) is that it is easy to clear the stack for the trip through south station. The 16 requires some planning to insure the stack is clean by the time it reaches the south station. Once there, the fireman is at the fire's mercy for a clean burn.

The final weekend, October 31 had perfect weather: warm and dry. Too bad that nobody told potential customers! The crowds were light all evening. One good thing was that the 9 emerged from the shop and pulled a train flawlessly for an hour. By midnight, the south station had been stripped of its spook house look and was well on its way to North Pole Express.

"Midwest Haunted Rails" (also known as "Ghost Train," "Spook Train," and a few other unmentionables) is over. This blog entry shows some of the highlights and lowlights of the four weekend event.

The event centers around the animated objects in the south station. A few new things come each year and some of the old things may not reappear. A comprehensive website containing many pictures of the south station's objects can be found at w w w . g h o s t t r a i n . o r g.

Saturday, October 11, was the first night of operation. Mid October can have weather ranging from "incredible" to "incredibly bad." With afternoon temperatures of 80F and a clear sky, "incredible" correctly described the weather.

Several shop crew volunteers rearranged cars to make the two Haunted Rail trains. Between the Old Threshers' Reunion and the two special operating events, the trains were a mess. The staff moved one car at a time to its destination train until the job was complete. While this should be a trivial operation, one car was particularly fussy and refused to pass backward through the Museum B switch, derailing in the process. An otherwise uneventful afternoon turned gray but the new MCRR CASE backhoe saved the day.

Two of the three steam locomotives (6 and 9) were fired up and ready on time. The crowds were light but enough were present to operate two trains for most of the evening.

The next weekend, October 17 and 18, tried our patience.

Friday's weather fell into the "incredibly bad" category. It was cool and rainy all day which made doing anything outside uncomfortable. The ground was still saturated from heavy rains a few days earlier. Our experience of a low Friday night turnout proved consistent with years past. Fortunately the hardware worked flawlessly.

Saturday was the opposite of Friday: warm, clear skies, a gentle breeze...and crowds that we've never seen! Anticipating the masses, all three locomotives were fired up. By 6 PM, the 6 was pulling passengers and the 9 was ready to hook up to its train only there was no engineer. The MCRR's Matt C. stepped into the 9's cab and was off to get the cars. After a successful air brake test, the 9 was ready for passengers. The 16's fire was banked in anticipation of it being needed to replace the 6 or the 9.

On 9's initial trip to the north station, everyone in the cab remarked that the engines didn't sound right. Oh well...just our imagination. With a full load of passengers, the 9 was on its way to the south station.

Then it happened: just 250 feet from the north station, the 9 stopped dead in its tracks (or more aptly, in its "track"). There were lots of MCRR crew members all scratching their heads about what happened. During the head scratching, Dustin B. ran across McMillan Park to get the 16 at operating pressure. Griffin W. raced back to get the 14, the diesel switch engine, with the intentions of pulling the 9 and its train to the north station, discharging its passengers and then pulling it to the shop.

The crowds kept building and were wondering what was going on. Hahaha...the shop crew was wondering what was going on! Meanwhile, engineer Eric S. was squeezing performance out of the 6 that no one had ever seen before. Fireman Abe S. had his hands full keeping the steam pressure high enough for the 6 to pull up the hill but not pop-off and keep enough water in the boiler. Later that evening, Abe remarked that he had never been so busy on that or any MCRR locomotive.

While the 6 was performing miracles in Eric skillful hands, the 16 was at pressure and was moved to the cars left behind by the 9. Murphy struck again; the 16's air brakes would not work! The 14 towed the 16 away and then it was hooked to the 9's train. With some jury rigging, electricity for the coachs' lights was secured and the 14 roared into service, operating for the rest of the evening.

A few volunteers in the shop ("Shop Supervisor" Mike E. and Jim B.) examined the 9's steam cylinders and found that the D valve linkage had come loose effectively setting the front cylinder into reverse while the center and rear cylinders were in forward motion. No wonder the 9 stopped so suddenly. By the time this was corrected, the other trains had been parked and the customers had left the park -- and it was midnight. For the next two weeks further investigations uncovered excessive drive train misalignment which only amplified the original D valve problem.

Weekend 3, October 24 and 25, were repeats of the previous weekend: cold and rainy on Friday, warm and clear on Saturday. The 6 and 16 worked as intended while the 9 absorbed hours of labor correcting the drive shaft misalignment. Having the 6 and 16 pleased the crowds (there is something about steam!) and the two engines pleased the crews.

The next few pictures show Jesse V. taking one of the 9's trucks apart to determine why the drive shaft was out of alignment.

The next picture shows Jesse holding a section of a bandsaw blade which was used as a shim by the previous owners of the 9, West Side Lumber. Not only were sections of band saw being used as shims, the adjustments had been welded in place, apparently to keep them from coming loose while in the field.

Fireman Dustin B. checks the fire inside the 16's boiler early in the afternoon.

With the 16 at full pressure, it was used to move the 9 back and forth so the staff could visually check the workings of the multiple drive shafts.

As the 16 is doing yard work, the 6 is being brought up to operating pressure.

After dark, the engines take on a different look. Here, the 6 passes the water tower at the north station.

Fireman Dave R getting a few laps of operating time with the 6's boiler in between his long shifts as "spook house" manager.

The 16 pulling into north station.

Fireman Dustin opens the firebox door to feed it some more coal for its trip to the south station. A nice thing about the oil burners (the 6 and the 9) is that it is easy to clear the stack for the trip through south station. The 16 requires some planning to insure the stack is clean by the time it reaches the south station. Once there, the fireman is at the fire's mercy for a clean burn.

The final weekend, October 31 had perfect weather: warm and dry. Too bad that nobody told potential customers! The crowds were light all evening. One good thing was that the 9 emerged from the shop and pulled a train flawlessly for an hour. By midnight, the south station had been stripped of its spook house look and was well on its way to North Pole Express.

Monday, November 3, 2008

A September work weekend

After the special event on Friday, September 12, several shop crew members took care of remedial maintenance on the 6 and replaced some ties on the yard's north end.

Everyone had noticed the compound air compressor shaking wildly on Friday. Close inspection uncovered all four mounting bolts were loose!

The following picture shows volunteer Roger R.prying the compressor away from the frame in order to free one of the mounting bolts. The overhead crane is attached to the lifting ring of the compressor for safety.

Shop crew volunteer Anita N. tightens the front lower mounting bolt. (Yes; women are welcome at the MCRR!)

Here, Anita tightens the set screws holding the fireman side grab rail. The grab rail had to be removed to access the top two bolts on the air compressor.

Shortly after completing the compressor project, the rains started -- and kept us from doing anything useful outside. After lunch (and whining about the rain) it was time for the monthly MCRR board meeting. The meeting filled our early afternoon until the rains finally stopped long enough to do the track work.

Several shop volunteers Dustin B. and Griffin W. are shown lifting the new tie across the rails.

The ballast needed rearranging before the new tie would slide in place. Between Jesse V. and Griffin W.,volunteer Paul K. is shoveling gravel out of the way to make room for the tie.

MCRR Board member Mike C. looks on from the back hoe while Griffin W. scrapes more gravel out of the way.

Dustin B. and Griffin W. maneuver the first of several ties in place.

Volunteer Brian B. sorts the good spikes from the junk spikes.

As usual, Dustin B. is standing in the way of progress. Track Supervisor Paul K. looks on while using a shovel to steady himself.

While Anita pulls the tie against the rail, Supervisor Paul shovels some ballast on her shoes and under the tie.

Not to be outdone by the Sup, Griffin pushes ballast under tie while Anita keeps it tight against the rail. Mike C. maintains a safe margin from the work area in the comfort of the backhoe.

Board member Jesse V. pounds a spike into the plate while Anita uses a pry bar to keep the tie tight against the rail.

Mike C. stretches while the laborers finish pounding the spikes.

Apparently Anita is interviewing for the Track Supervisor position by resting against the pry bar and watching knowingly as the laborers pound spikes in place.

With Dustin, Jesse and Griffin all promoted to Supervisor, Brian tightens a bolt. Notice how his brute strength has bent the track wrench.

Dustin throws the last few shovel fulls of gravel between the gap.

Everyone had noticed the compound air compressor shaking wildly on Friday. Close inspection uncovered all four mounting bolts were loose!

The following picture shows volunteer Roger R.prying the compressor away from the frame in order to free one of the mounting bolts. The overhead crane is attached to the lifting ring of the compressor for safety.

Shop crew volunteer Anita N. tightens the front lower mounting bolt. (Yes; women are welcome at the MCRR!)

Here, Anita tightens the set screws holding the fireman side grab rail. The grab rail had to be removed to access the top two bolts on the air compressor.

Shortly after completing the compressor project, the rains started -- and kept us from doing anything useful outside. After lunch (and whining about the rain) it was time for the monthly MCRR board meeting. The meeting filled our early afternoon until the rains finally stopped long enough to do the track work.

Several shop volunteers Dustin B. and Griffin W. are shown lifting the new tie across the rails.

The ballast needed rearranging before the new tie would slide in place. Between Jesse V. and Griffin W.,volunteer Paul K. is shoveling gravel out of the way to make room for the tie.

MCRR Board member Mike C. looks on from the back hoe while Griffin W. scrapes more gravel out of the way.

Dustin B. and Griffin W. maneuver the first of several ties in place.

Volunteer Brian B. sorts the good spikes from the junk spikes.

As usual, Dustin B. is standing in the way of progress. Track Supervisor Paul K. looks on while using a shovel to steady himself.

While Anita pulls the tie against the rail, Supervisor Paul shovels some ballast on her shoes and under the tie.

Not to be outdone by the Sup, Griffin pushes ballast under tie while Anita keeps it tight against the rail. Mike C. maintains a safe margin from the work area in the comfort of the backhoe.

Board member Jesse V. pounds a spike into the plate while Anita uses a pry bar to keep the tie tight against the rail.

Mike C. stretches while the laborers finish pounding the spikes.

Apparently Anita is interviewing for the Track Supervisor position by resting against the pry bar and watching knowingly as the laborers pound spikes in place.

With Dustin, Jesse and Griffin all promoted to Supervisor, Brian tightens a bolt. Notice how his brute strength has bent the track wrench.

Dustin throws the last few shovel fulls of gravel between the gap.

Subscribe to:

Posts (Atom)